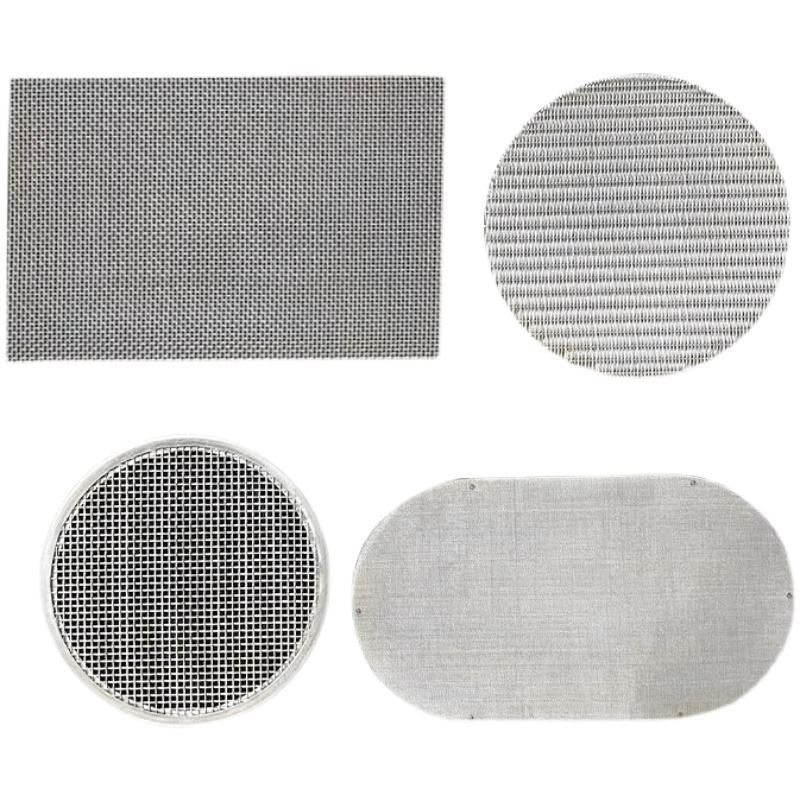

Stainless Steel Coffee Sintered Tablets

Applicable tutorials

1. Press the coffee powder with a tamper

2. Put in the appropriate size of the water separation mesh

3. Put the handle of the coffee machine on the brewing head

4. Observe the liquid

Why use a secondary water distribution network?

The secondary water distribution net effectively separates the coffee powder and the brewing head to keep it clean

Characteristics of sintered mesh

1. High strength and good rigidity: It has high mechanical strength and compressive strength, good processing, welding and assembly performance, and easy to use.

2. Uniform and stable precision: Uniform and consistent filtration performance can be achieved for all filtration precisions, and the mesh does not change during use.

3. Wide use environment: It can be used in the temperature environment of -200 ℃ ~ 600 ℃ and the filtration of acid and alkali environment.

4. Excellent cleaning performance: good countercurrent cleaning effect, can be used repeatedly, and has a long service life (can be cleaned by countercurrent water, filtrate, ultrasonic, melting, baking, etc.).

Sintering production process

1. Low temperature pre-burning stage. At this stage, the recovery of metal, volatilization of adsorbed gas and moisture, decomposition and removal of forming agent in the compact mainly occur;

2. Medium temperature heating sintering stage. At this stage, recrystallization begins to occur. In the particles, the deformed grains are restored and reorganized into new grains. At the same time, the oxides on the surface are reduced, and the particle interface forms a sintered neck;

3. High temperature heat preservation completes the sintering stage. Diffusion and flow in this stage are fully carried out and close to completion, forming a large number of closed pores, and continue to shrink, so that the pore size and total number of pores are reduced, and the density of the sintered body is significantly increased.